Polymer anti-crack paste for repairing concrete road cement road

Product Description

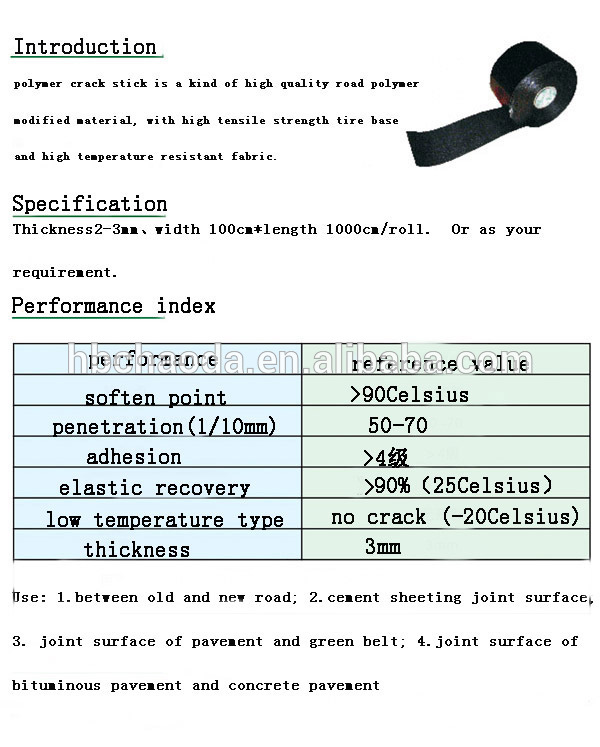

polymer crack stick is a kind of high quality road polymer modified material, with high tensile strength tire base and high temperature resistant fabric.

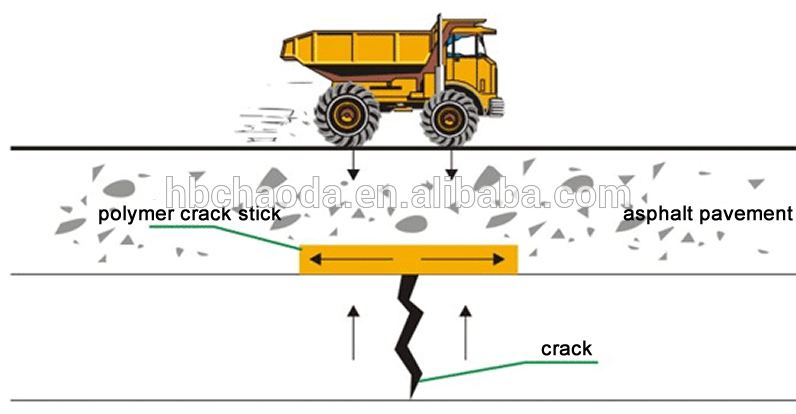

Principle

Mechanical effect: High-molecular polymer materials as a stress absorbing membrane, can increase the likelihood of vertical cracks of the grassroots level, which develops along the interface in the horizontal direction, thus delaying the time that the road crack reflectsto the road table.

Bridging role: After crack is into the asphalt concrete pavement, the double bridging function of geotechnical synthetic material and high temperature resistant fabric makes the cracking section has a certain tensile ability, reduce the deformation of the crack, and the stress concentration of crack tip.

Interlocking: Improve capacity of the shear load transfer resistance of the cracking section. The molecular material of asphalt base has a relatively low temperature, which makes the material don’t change it’s shape; And the good waterproof effect prevents from the infiltration of water for the cracking road table.

Advantage

Polymer crack stick overcomes the interface caused by the crack for only using geotechnical cloth and glass fiber grill, and the interface influences the force condition of asphalt mat and the crack resistance; Polymer crack stick also overcomes the translation,fold in the paving process of geotechnical cloth and glass fiber grill, which influences upper and lower structure layer adhesion. The asphalt base stress absorbing membrane can only absorb stress, but can not resist to residual stress and disperse stress, polymer crack stick gives a good solution for this. This special structure can not only prevent from cracking, but also has a good effect for water infiltration, especially as for water infiltration after the road frosts crack, it has a good low temperature resistance.

Polymer crack stick use technology guide

Width:

After years’ use for polymer crack stick and the mechanics model analyses for stress caused by crack, we have a solution for the following four width productions:

- 24cm suggests to use where there are no cracks around the crack or other non damage of vertical/horizontal crack(width is 1-3mm).

- 32cm suggests to use in the asphalt pavement and concrete pavement, especially vertical/horizontal crack(width is 1-3mm), random crack, mild crack surface, cold joints and use in the joints for different pavement materials(asphalt or concrete ).

- 48cm(96cm) suggests to use for the crack of asphalt and concrete surfaces, which have been repaired or cracked pouring, severe cracking or damage area and curing of the bridge deck pavement and so on.

Surface treatment adhesive crack stick

1.The sundries such as dust and water In the adhesive surface must be cleaned up, and keep pavement dry and clean.

2.The joint whose width is between 5-19mm must be cleaned up and filled with fluid sealant.

3.The joint and subsidence area whose width is between 19-50mm must be cleaned up, and use glue sand, sealant or hot asphalt mixtures to fill in and compaction to existing height.

4.The crack or pit slot of more than 50mm width must be cleaned up first, and use glue sand or hot asphalt mixtures to fill in and compaction to existing height.

5. For the different height of joint and subsidence area, it must do leveling treatment.

6.For the bulges such as the bridge desk,pavement,iron nail, it must be cleaned up or do leveling treatment until it’s smooth.

The environment situation requirements for using polymer crack stick

1. It should be used for the surface temperature is equal to or greater than 21℃.

2. If the surface temperature is lower than 21℃, it is suggested to roast by low temperature fire, do not use too much fire, surface melting is ok. Or use the regular emulsion adhesive layer oil, about 0.5~1.0kg/m is ok.

Lay of polymer crack stick

1. Don’t tear the isolating membrane before paving.

2. The roll material should be strained when use the polymer crack stick, and it should be neat, non crease, non tilting.

3. If there is overlap in the process of paving, the overlap length should be between 50~125mm, and no more than double-deck overlap.

4.It is suggested to have the rolling at least three times by rubber tireroller after paving the polymer crack stick.

5.Finish the pave of polymer crack stick, there should be a asphalt mixture paving asap, no more than 24 hours in this period, at the same time,avoiding the machine tool such as construction vehicle walking or withdrawing on the material.

Mat coat for hot asphalt mixtures

1.After the correct paving of polymer crack stick, it should be closely with the upper construction and avoid being affected with damp and rain.

2. After paving of polymer crack stick, spreading sticky layer of oil such as emulsified asphalt according to construction specifications of hot asphalt mixtures.In order to avoid the vehicle or paver bonding polymer crack stick, some gritty cover stone or mixtures can be spread on the polymer crack stick.

3.The thickness of the hot asphalt mixtures on the polymer crack stick should be more than 40mm.

4.In the process of compaction, roller should be adjusted to the position of the low amplitude and high frequency, if the roller amplitude is too large, maybe there is a small amount of flaking in the position of polymer crack stick.

Picture

If you are interested in our products, kindly contact us. Best quality and competitive pricewill be offered to you.

More information please contact:

Trade Manager: cn1513931323

Skype:

Tel:

Whatsapp: +86